Until now, the entry point into watch repair has been either through apprenticeship, self learning via books, or entry to a Horology course with a technical college.

Whilst I believe apprenticeship is the absolute best way to learn this trade, opportunities are getting more and more scarce. Many college watch repair courses are being scrapped because of lack of teachers, lack of funds, or lack of students. I hate to say it, but the promotion of watch repair lessons, and Horology to school students as a viable career option, is very rare.

There are several top end courses available to the lucky few, W.O.S.T.E.P as an example, but these specialised watch repair courses are notoriously difficult to gain entry, with many places being reserved for students sponsored by one of the large watch houses.

There are also many fantastic book resources available for learning Watch Repair techniques, and we should not overlook these resources. It is very important to learn from the masters of past. However, many of these books are very dated and do not come close to covering modern watch calibers, tools and techniques.

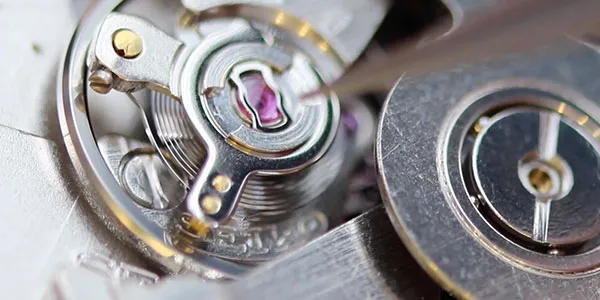

This course is unique because it discusses tools and watch repair techniques in a modern way, high definition crystal clear video streamed directly to your computer, cellphone or tablet.